In this guide, we will explore:

- What is PHA?

- What are the benefits of PHA?

- How PHA is being used for straws?

- How can you dispose of PHA straws?

- Is PHA allergen-free?

- Is PHA used in skincare products?

- What products is PHA used in?

What is PHA?

PHA, or polyhydroxyalkanoates, is a bioplastic produced by microorganisms. It's gaining popularity due to its incredible ease of compostability compared to other bioplastics like PLA (polylactic acid) and for it's versatility. PHA looks, feels and functions like plastic but without the environmental effects.

Made using plant feedstocks including waste, PHA is bio-based biopolymer that can be created using bacterial fermentation with vegetable oils, sugars, starches, and even methane and wastewater. This process mimics what is found in nature joining proteins, starch, and cellulose. The video below shows a helpful demonstration.

What are the benefits of PHA?

PHAs offers several significant benefits from environmental impact to material properties and medical applications.

Environmental Benefits of PHA

- Biodegradability: PHAs are fully biodegradable in various environments, including soil, marine, and compost settings. This helps reduce the accumulation of plastic waste and its harmful effects on ecosystems.

- Renewable Resources: PHAs are produced from renewable resources, such as plant oils and sugars, making them a more sustainable option compared to petroleum-based plastics.

- Reduced Carbon Footprint: The production of PHAs typically results in lower greenhouse gas emissions compared to conventional plastics, contributing to a reduction in overall carbon footprint.

Material Benefits of PHA

- Versatility: PHAs can be tailored to possess a wide range of properties, from being rigid and tough to flexible and elastic. This makes them suitable for various applications, including packaging, agricultural films, and consumer goods. They're also FDA approved for food contact.

- Thermal Stability: Certain types of PHAs exhibit good thermal stability, making them suitable for applications that require exposure to higher temperatures.

- Barrier Properties: PHAs often have good barrier properties against water vapor and gases, which makes them ideal for food packaging and other applications requiring moisture and oxygen barriers.

Medical and Biomedical Applications of PHA

- Biocompatibility: PHAs are biocompatible and can be safely used in medical applications, such as sutures, wound dressings, and tissue engineering scaffolds.

- Controlled Degradation: The degradation rate of PHAs can be controlled by adjusting their composition, making them useful for drug delivery systems where gradual release of the drug is required.

- Non-Toxicity: Degradation products of PHAs are non-toxic, which is critical for applications inside the human body.

Economic and Industrial Benefits of PHA

- Diverse Feedstock: PHAs can be produced from a variety of feedstocks, including agricultural by-products and waste materials, potentially lowering production costs and enhancing economic viability.

- Process Compatibility: PHAs can be processed using conventional plastic manufacturing equipment, which facilitates their integration into existing production lines without the need for significant modifications.

How PHA is being used for straws?

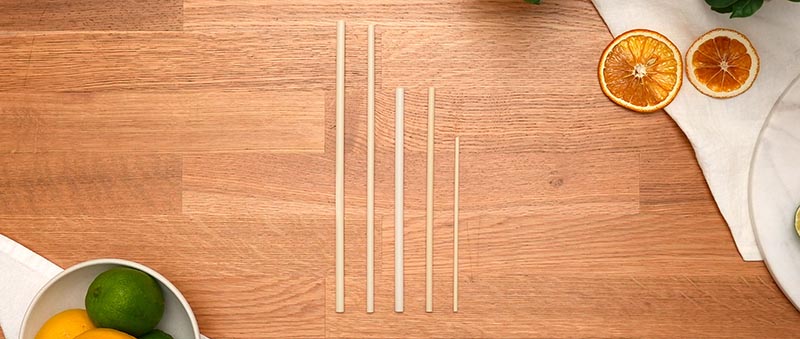

Since PHA is such a versatile and environmentally-friendly material, PHA straws are taking the beverage world by storm.

PHA straws look, feel, and work just like conventional plastic straws. But, unlike plastic straws, they don’t harm ecosystems or marine animals by breaking down into micro-plastics like petroleum-based straws.

Instead, PHA straws can be composted or will break down completely in a marine environment. Beverage straws, cocktail straws, smoothie straws and more are being created using this adaptable material.

Good Start Packaging's PHA straws start out as canola or soybean seeds. Once harvested, the seeds are crushed and refined into oil. The byproducts of this process are what end up in this material. Our straws are made from Nodax PHA made by Danimer Scientific

In a controlled fermentation environment, soil bacteria work with canola and soy byproducts to create PHA. The end product is heat- and UV-resistant and FDA-approved for food contact.

How can you dispose of PHA straws?

Disposing of PHA straws can be done in several environmentally friendly ways due to their biodegradable nature, including:

- Industrial Composting: PHA straws can be disposed of in industrial composting facilities, which provide the optimal conditions of temperature, humidity, and microbial activity needed for rapid and complete biodegradation.

How: Check if your local waste management services accept compostable plastics and ensure you place the straws in the appropriate compostable waste bin.

- Home Composting: Although more time consuming than industrial composting, PHA straws can also be composted at home.

How: Place the straws in your home compost bin. They will biodegrade over time, although this process might be slower and dependent on maintaining proper composting conditions (aeration, moisture, and temperature).

- Organic Waste Bins: If your municipality has an organic waste collection program, you can dispose of PHA straws in these bins. The waste is typically sent to composting facilities where it can biodegrade effectively.

- Landfill: While not the most ideal due to slower degradation rates compared to composting, PHA straws will eventually biodegrade in a landfill environment.

How: If no composting options are available, dispose of the straws in the general waste bin. While they will break down over time, the process will be slower due to the less favorable conditions in a landfill.

- Environmental Disposal: PHA straws are marine degradable, meaning they will biodegrade in marine environments. However, intentional disposal in natural environments should be avoided to prevent litter and potential harm to wildlife.

- Recycling: Currently, there are limited recycling programs specifically for PHA materials. However, it is essential to keep an eye on evolving waste management practices, as new recycling technologies and programs may become available.

The most environmental responsible way to dispose of PHA straws is through composting. Always check local waste management guidelines to ensure proper disposal and take advantage of composting facilities or organic waste collection services where available.

Is PHA allergen free?

Yes, PHA is allergen-free due to their biocompatibility and absence of proteins. While some question this due to the use of soy as a base material, the refined oils of the soy seeds are used and not the soybeans themselves.

Is PHA used in skincare products?

PHA is an easily confused material due to having a matching acronym. Polyhydroxy acid and Polyhydroxy alkanoate are, in fact, two different classes of the compound. The former is an acid and the latter alkanoate is an ester.

Polyhydroxy acid is popularly used in the skin care industry for gentle exfoliation of skin cells and is similar to alpha hydroxy acids and beta hydroxy acids (AHAs or BHAs).

What products is PHA used in?

The versatility of PHAs makes them suitable for a broad spectrum of applications, from everyday consumer products to specialized medical devices and environmental solutions. Their biodegradability and sustainable makeup offer a promising alternative to conventional plastics.

For example, PHA is used in food packaging such as straws, cutlery, and disposable cups given their ability to stand up to moisture. PHA is also used in medical and biomedical products like sutures and wound dressing given their biocompatibility and controlled degradation rates. You can find PHA in biodegradable mulch, shampoo bottles, cosmetic containers, textiles, waste bags, eco-friendly lubricants and hydraulic fluids, and even interior parts for vehicles, such as panels and trim components!